100th

Anniversary

1919 - 2019

100th

Anniversary

1919 - 2019

Power centre of Thermal Separation Technology

Buss-SMS-Canzler celebrates 100th anniversary and looks optimistically into the future

Innovative strength is the most important of the many competencies that distinguish our company. This spirit - not to remain stuck in the past, but to progress and break new grounds continually - allowed us to celebrate this great anniversary in 2019.

At Buss-SMS-Canzler, innovative strength is not an empty formula but part of the working life.

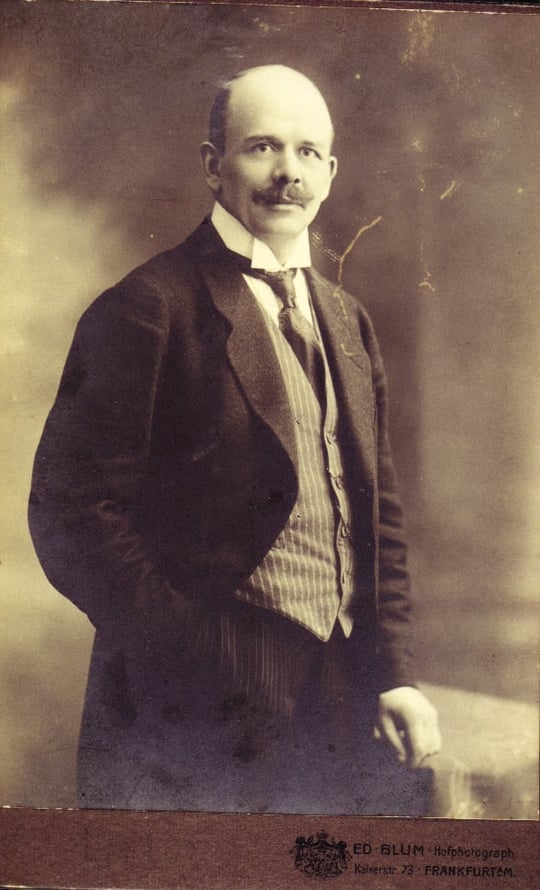

The reason is deeply rooted in our founder and the year of foundation. In 1919 Germany struggled for its future after a lost World War I and Richard Samesreuther, a 38-year-old war returnee without large financial assets of his own, nevertheless dared to found the Samesreuther & Co. OHG in Butzbach - as we know today with great success!

Richard Samesreuther

Samesreuther & Co. OHG started on April 1, 1919 and was entered in the Commercial Register of the Hessian Local Court in Butzbach on April 9, 1919.

Although he was dependent on outside capital, and the general economic conditions were not good, he believed in his own as well as his employees' professional skills, inventiveness and creativity. With these conditions and the necessary bit of luck, three extremely difficult decades until 1949 were mastered - with the restrictions of the post-war order from November 1918, two economic crises, two currency reforms, the disintegration of the Weimar Republic, the "Third Reich" and the Second World War with its consequences.

This was followed by seven more decades in a politically more stable and peaceful period, during which the company changed constantly, not only in terms of its product range.

The takeover by the new majority shareholder - Müller-Schuss KG in 1964 - was followed by the integration into the new Samesreuther Müller Schuss GmbH, a group of companies with five production sites. Later, the company was taken over successively by two Swiss industrial groups: first by Luwa AG in 1972, which created Luwa-SMS GmbH, and then by Buss AG in 1983, which created Buss-SMS GmbH. This was followed in 1998 by the takeover by the US-American UPE Inc. and finally the takeover by the company's own management in 2003.

Together with the important step of the takeover of the thermal separation technology of Canzler GmbH in 2003 by the former Buss-SMS GmbH, the current company name Buss-SMS-Canzler GmbH explains itself. It also explains the locations of the company with Butzbach as headquarters and founding location of the company Samesreuther, as well as Pratteln and Düren as branch offices and former locations of the companies Buss and Canzler.

Richard Samesreuther

More important, however, is the fact that the combination of the expertise and experience of the three companies Samesreuther Müller Schuss, Buss and Canzler has created a company with a unique pool of reference plants worldwide and an equally unique team of employees, a power centre for thermal separation technology.

This becomes evident, considering that the three original companies all had their core competences in process engineering and sophisticated process equipment fabrication. The associated knowledge of the employees was and is being secured and further developed by maintaining the locations.

The different parts of the company name stand for certain periods within the company's history. The founding company has not only developed monolytically out of itself, but also in exchange with the constantly changing immediate business environment. Initially, it was an owner-managed company, it then became part of a larger group of companies at regional level, eventually ending up with Swiss industrial groups and, after a period with US owners, became owner-managed again.

Since its foundation in 1919, the company has achieved an impressive series of technological milestones, only a few of which should be mentioned here:

- By 1921, a workshop for autogenous, electrical and thermite welding had been set up, in particular for copper welding.

- In 1928, after a long period of development, solid or half-pipes were welded directly onto cylindrical vessels for the first time. The cast-iron vessels with cast-in coils, which had been customary until then, disappeared and respective patents were granted.

- In 1931, further patents followed for the invention of the welded double jacket with projection welding. The invention was based on burst tests and joint investigations with the TH Karlsruhe.

- In 1949, Patent application for the vertical cylindrical thin film evaporator with rigid blade rotor.

- In 1958, following a joint development between Bayer, Samesreuther and Luwa, a patent was filed for a vertical thin film evaporator with an internal condenser for operation under high vacuum - the Samvac.

- In 1969, after extensive development work, the first horizontal thin film dryers were delivered. While the vertical thin film dryer offers short residence times with high heat transfer rates, the horizontal thin film dryer has significantly longer residence times and allows the transition of viscous phases.

- With the delivery of the first Filmtruder in 1970, it was possible to use the thin film technology for highly viscous products as well. Depending on the application, the Filmtruder has a customised rotor to generate the desired shearing and conveying effect with a narrow residence time distribution and minimum temperature stress.

- In 1980, the first horizontal thin film dryer for sewage sludge drying was delivered, a key application of the company until today.

- In 1985, the Filmtruder was used for the first time in the pilot test centre for the production of the spinning solution of the new cellulose fibre Lyocell. A key application has been developed, which is of great importance until today.

- In 1991, the largest Short Path Evaporator order in the company's history was delivered to Malaysia, 7 Samvac for wax distillation.

- In 1998, the development of the horizontal, large volume twin-shaft processors, which we know today as Reacom and Reasil, began. The processors completed the range towards longer residence times with narrow residence time distribution and good self-cleaning for viscous and solid products. Over the years, a number of patents have been developed.

- In 2000, delivery of the first inductively heated thin film evaporator, a short path evaporator for operation up to 450°C for the concentration of coal tar pitch. The application has been so successful that the same customer ordered two more complete plants in later years.

- In 2006, the largest built Reactotherm with 10,000 l was delivered to Korea as a reactor for the production of superabsorber polymers. At the same time, built on our historic roots, the company was renewing the copper lining of a reactor with a diameter of 3.4 m and a length of 14.5 m for a Dutch customer.

- In 2008, for the first time two horizontal thin film dryers with a heating surface of 70 m² each have been installed on a ship. The dryers are part of a plant for extracting oil and phospholipids from krill.

- In 2009, the first two industrial Reasil processors for a continuous polymerisation reaction were built and delivered. A Malaysian customer placed an order for the supply of a complete plant for the esterification and distillation of monoglycerides.

- In 2010, the first Hyvap, a newly developed horizontal, unilaterally mounted rigid blade thin film evaporator for the pharmaceutical industry, was ordered.

- In 2012, the first industrial CFT dryer for the recovery of TDI from production residues was sold against established, but technologically not comparable competitor technology. The dryer operates with a mechanically generated fluidised bed and is capable of drying even the most demanding residues.

- In 2014, the first horizontal thin film dryers with a heating surface of 125 m² were built; they were delivered to China for sewage sludge drying - the largest thin film dryers worldwide.

- The first industrial Devosil, a high viscosity short path evaporator, was built in 2018. The development of this new technology already began in 2012.

- In 2019, the company received the largest order in its history. 10 horizontal thin film dryers and 10 linear dryers for a sewage sludge drying plant in Shanghai were sold for EUR 20.5 Million.

This list shows how the company has continuously refined its technologies over the past 100 years in order to meet the constantly changing requirements of the market and the customers, and to offer solutions by using our own potential: Improving the existing and developing optimum solutions to new requirements.

Over the decades, central business areas have repeatedly broken away and had to be replaced by new ones, or the requirements have changed fundamentally. The extinction of steam locomotives, the end of the nuclear power plant era, the increasing competition for the chemical raw material crude oil by renewable raw materials with more and more new products, new and better product qualities, larger production capacities and the increasing importance of sustainability in production processes are just a few examples.

Buss-SMS-Canzler considers change as an opportunity and not as a threat.

Due to its large number of industrial references and its broad technology program as well as its range of applications, the company is a global leader in thermal separation technology and the world market leader in the thermal concentration of substance mixtures, which are difficult to handle.

The central secret of the company's success is its staff: around 250 highly qualified and motivated employees - of whom approx. 15% are master craftsmen or technicians, around 55% have completed vocational training and approx. 30% have a graduate degree, some a PhD. Many of them - and we are particularly proud of this - joined the company at an early age, either to complete a vocational training or to start their careers after graduating from university, and have stayed with us. Similarly, it is regularly the case that young colleagues further qualify as master craftsmen or technicians after having completed their vocational training. This grown staff forms the solid base, on which the company is built.

We are proud of the fact that even after 100 years of company history, our employees are always looking for the best solution with the same commitment, knowledge and experience. We are never satisfied with the second best solution, even if it is sometimes a challenge to find it. Just like 100 years ago.

At this point we would like to quote the audit manager of the revision audit for the quality management system according to ISO 9001 from 2017:

"I have no customer who can handle such demanding projects. You have a motivated team at all locations. I have not noticed any deviations. I am very satisfied".

Buss-SMS-Canzler GmbH