CFT Dryer

It combines the advantages of convective fluidised bed drying with contact drying

CFT Dryer

It combines the advantages of convective fluidised bed drying with contact drying

CFT dryers offer an economic process for sticky products

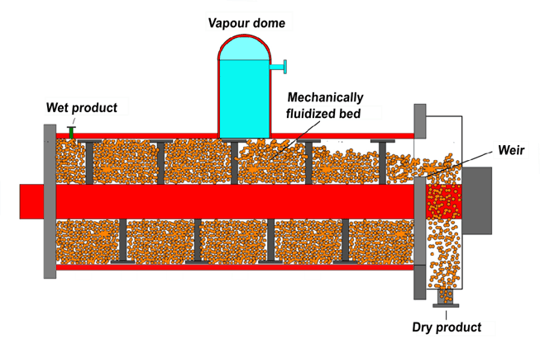

Operating Principle

The Combined Fluidisation Technology dryer (CFT dryer) offers an economic process for sticky products. CFT dryers combine the advantages of convective fluidised bed drying with contact drying.

The CFT works with a hot mechanically fluidised bed. The feed material is distributed into this bed. It is fluidised by a rotating paddle system. Inside the fluidised bed the wet product is evenly distributed throughout the dry product. The volatiles evaporate instantly in contact with the hot particles, i.e. new solids are created at the location of evaporation.

CFT dryers allow the handling of products, which cannot be handled in other types of contact dryers. Highly viscous, pasty, sticky, crust-forming phases do not exist.

Advantages

The unique benefits of the CFT dryer are:

- Drying of crust-forming feeds

- Drying of products with extreme sticky and long transition phases from paste to solid

Typical applications

The CFT dryer is used in the following applications:

- Tar and paint sludge

- TDI recovery

- Drilling muds

- Soil decontamination

- Various sticky slurries

- Starches and proteins

Get your free copy!

Inside Excellence in process technologies:

We are number 1 in thin film evaporation technology and a global leader in drying and high viscosity technology.

Take a look inside our technology brochure: