High Viscosity

Technology

With a unique range of high viscosity processors

High Viscosity

Technology

With a unique range of high viscosity processors

Customised solutions for highly viscous products

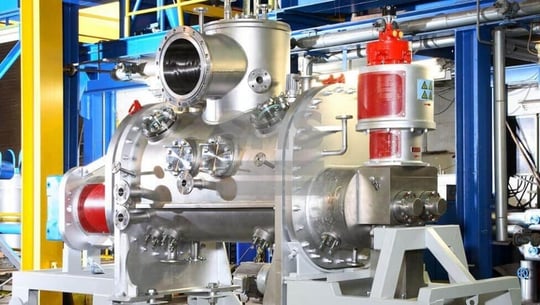

SMS offers its customers not only a unique range of high viscosity processors but also the respective process technology. Our product program provides customised solutions for products which are viscous and difficult to handle. The processors operate across a wide range of viscosities and residence times.

In addition to the long-standing and well-known thin film processors Filmtruder and Viscon, SMS has developed single- and twin-shaft horizontal, large volume processors of the types Reactotherm, Reasil and Reacom.

Design criteria that determine which technology is used include:

- Residence time

- Viscosity

- Pressure

- Temperature

- Vapour volume

- Mixing requirement

- Melt vs. friable solids

- Capital and operational cost

Typical Applications

Functions

- Evaporation

- Devolatilisation

- Heat exchange

- Mixing

- Reaction

- Sublimation

- Resource recovery

Characteristics

- Viscous / Elastic

- Sticky

- Phase change

- Solidification

- Foaming

- Heat-sensitive

- Shear-sensitive

Parameters

- Adjustable residence time

- Batch or continuous

- Plug flow

- Efficient heat transfer

- Adjustable vacuum / pressure

- Heating / cooling

- Multiple feed ports

- Multiple discharge options

- Self-cleaning