Thin Film

Dryer

In one step from liquid to solid

Thin Film

Dryer

In one step from liquid to solid

Vertical and horizontal thin film dryer

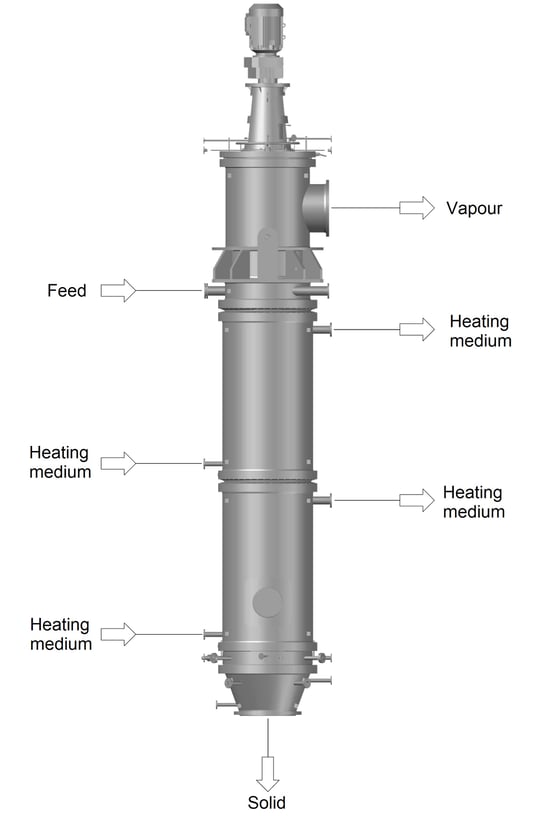

Operating principle of a vertical thin film dryer

The vertical thin film dryer consists of a cylindrical, vertically arranged body with heating jacket and a rotor inside. The rotor is equipped with rows of pendulum blades all over the length of the dryer. The hinged blades spread the wet feed product in a thin product layer across the heated wall and mix the product layer material intensively. Thus, the volatile components evaporate continuously from the product layer at high evaporation rates. The hinged blades are designed with a minimum gap to prevent product fouling on the heating surface, but they are never in contact with the heated wall.

The product enters the dryer at its top. After having been heated to the boiling point, the evaporation starts. In the slurry zone first solids form, and with progressing evaporation of the volatiles and continued shearing by the hinged blades the paste breaks up to powder. The final solid product is discharged by gravity via a suitable air lock at the bottom of the dryer.

Advantages

The unique benefits of the vertical thin film dryer are:

- In one step from liquid to solid

- Small product hold-up

- Short residence time ensures minimal product degradation

- Fast start-up and shut-down

- High performance even when scaling

Typical applications

The vertical thin film dryer is used in many applications:

- Chlorides, bromides, sulfates

- Glycerine recovery

- Carbonates, phosphates

- Silane recovery

- Silicon, silicon carbide

- Sodium formate

- Agrochemicals (atrazine etc.)

- Waste water and spent liquors

- Benzosulfic acid

- Solvent recovery from waste

- Xanthates

- Dyes and pigments

- Boron carbide, boron nitride

- Food, caffeine, condiments

- Animal feed

- Lithium hydroxide monohydrate

Operating Principle of horizontal thin film dryer

Horizontal thin film dryers are continuously operating contact dryers and are used for a broad range of applications under vacuum, atmospheric pressure and overpressure. They consist of a horizontally arranged heated shell with end covers and a rotor with bolted-on blades. The wet product fed through the inlet nozzle is picked up by the rotor blades, applied to the hot wall and simultaneously conveyed towards the outlet nozzle at the opposite end of the body.

The generated vapours are streaming counter-currently to the product flow and leave the dryer close to the feed nozzle. Evaporating and conveying capacity are adapted by the appropriate rotor blade arrangement.

Entrained particles from the dry zone are removed in the wet zone. Moisture levels of less than 1 % can be achieved. The residence time of the product typically is between 5 and 15 minutes.

Horizontal thin film dryers are also suitable for other applications apart from drying such as solid particle cooling and product melting. The outstanding heat transfer rate for hot solid products enables cooling of large amounts of solids without air in one compact machine compared to usually used cooling screws. In product melting, e.g. the melting of urea, the particles are heated and melted inside the dryer. The melt can be mixed with other liquid and solid additives to improve the properties of the final products.

Advantages

The unique benefits of the horizontal thin film dryer are:

- Broad range of feed properties: liquids, pastes, solids

- High flow rates per unit based on thin film principle

- Drying of products which pass a sticky phase from paste to solids

- Small product hold-up in dryer

- Fast start-up and shut-down

- No residual product inside at standstill

Horizontal thin film dryers

Typical Applications

Environment:

- Sewage sludge

- Industrial sludge

- Refinery sludge

Chemicals:

- Catalysts

- Carbon, carbon black

- Limestone

- Lithium salts (e.g. for batteries)

Polymers:

- Polyvinyl oxid

- Terephthalic acid

Pharmaceuticals:

Food:

- Cocoa

- Flour

- Sweets

- Pectin

Product melting and particle cooling:

- Melting of urea granulates

- Cooling of particles from upstream drying

Get your free copy!

Buss-SMS-Canzler offers tailor-made vertical and horizontal thin film dryers. Take a look inside our flyer: