Polymers

& Fibres

Substantial part of what we use everyday

Polymers

& Fibres

Substantial part of what we use everyday

Diversity - viscosity defines the equipment

The production of polymers and fibres needs equipment which is able to handle materials in a wide range of viscosities. Therefore, SMS provides equipment like short path evaporators for wax distillation, thin film evaporators for monomer separation, high viscous thin film processors in fibre production and high viscous large volume processors for devolatilisation and chemical reactions in polymer production. Especially the applications of the SMS high viscous processors need the development of processes which are adapted to the special requirements of the respective production process. These developments are supported by our test centre which is equipped with lab-scale and pilot-scale equipment covering our product portfolio.

- Cellulose triacetate

- Epoxy resin

- Formaldehyde

- Paraformaldehyde

- Nonylphenole

- Nylon 6, Nylon 66

- Phenole resin

- Polyacrylonitrile

- Polycarbonate

- Polyetherimide

- Polyester

- Polypropylene

- Polystyrene

- Polyurethane

- Polytetrahydrofuran (PTMEG)

- Polyvinyl acetate

- Polyvinyl pyrrolidone

- Silicone

- Silicone resin/oil

- Wax

Get your free copy!

Inside Excellence in process technologies: We are number 1 in thin film evaporation technology and a global leader in drying and high viscosity technology. Take a look inside our technology brochure:

Technologies

Evaporation Technology

We offer the world’s largest selection of thin film evaporators, and we build customer-specific equipment for the evaporation of materials which are difficult to process such as viscous, fouling, and heat-sensitive liquids.

Drying Technology

Depending on the requirement, we combine and customise drying processes and components to suit the product properties so that, for example, toxic or explosive materials can be safely and efficiently processed.

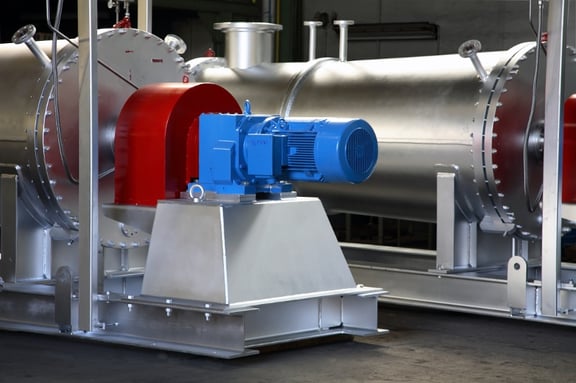

High Viscosity Technology

Our thin film processors and large volume reactors for the manufacture and preparation of polymers are world leaders and guarantee the very highest quality and efficiency as well as excellent process results.

References

The German way of joint innovation

Recognising innovation is continuous optimisation: Innovation is an evolutionary process which continuously creates added value for our customers.

- Cooperation with our customers

Working with our customers results in continuous enhancement of the functionality and efficiency of their plants. This is our main driving force of joint innovation. - Challenging of "traditional" processes

Even processes which have been performed successfully over the years may have potential for innovation, sometimes in minor details and components and sometimes in entire process steps. - Innovative tools as a base for innovative solutions

Recent developments in computation allow deep insights into process details, thus generating new knowledge as a base for innovation.