Smart Equipment:

SMS Mechanical Seal

Smart Equipment:

SMS Mechanical Seal

SMS equipment 4.0 – function and importance of smart mechanical seals

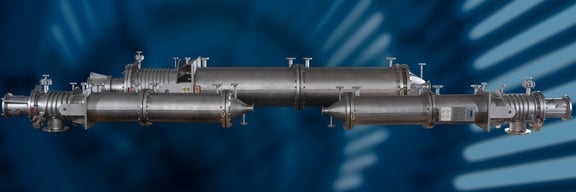

SMS has over 60 years of experience in the production and application of equiment for demanding thermal separation tasks. Our solutions are characterised by a relentless pursuit of excellence and innovation, offering versatility in orientation, shape and specialised rotor designs.

An essential component of our equipment is the mechanical seal for the shaft feedthrough. In vacuumoperated processes like thin film evaporation or drying, sealing the rotor shaft with a mechanical seal is essential to prevent air intake. Due to the importance of this component, we have applied our expertise to the development of an innovative mechanical seal for a variety of industrial applications. Monitoring offers vital data for predictive maintenance, enabling quick decisions.

The advantages of the SMS mechanical seal

Thanks to our continuous technological advancements and successful cooperation with our competent partner Metax Kupplungs- und Dichtungstechnik, we have developed a mechanical seal that meets the high requirements of modern industrial plants.

High Performance

The SMS mechanical seal is characterised by its high-quality and innovative materials which are already used as standard.

Easy Maintenance

Simple and cost-efficient maintenance.

24/7 Monitoring

Continuous 24/7 monitoring identifies seal problems in real time, allowing proactive measures to avoid downtimes and ensure maximum operational time.

Sensor Technology

Condition monitoring in real time using the latest BestSens sensor technology.

Sustainability

Fulfilling the environmental requirements. Sustainable usability of the machines by conversion to improved equipment.

Intelligent Analysis

Industry-ready control cabinet with on-site IT and cloud infrastructure. Warnings anytime and anywhere: connection to cloud and mobile devices.

The best choice for your equipment

The SMS mechanical seal offers exceptional flexibility and adaptability for existing SMS devices. The mechanical seal and sensors for monitoring can be integrated into up to 80% of existing thin film evaporators, making them ideal for the digital expansion of demanding industrial plants where reliability and efficiency are of utmost importance.

In short, the SMS mechanical seal is the perfect choice for companies that look for a future-oriented, reliable and high-performance solution. With our innovative technology and continuous monitoring, you can be sure that your systems are optimally protected and working smoothly.

Rely on our many years of experience and choose the SMS mechanical seal - the smart choice for your success!

Contact our specialists today:

Technologies

We are the number 1 in thin film evaporation technology and a global leader in drying and high viscosity technology. We develop and construct plants and equipment for such processes as the evaporation, drying and processing of highly viscous materials. Solutions that are exactly as you need them – exceptionally precise, efficient and, when necessary, highly innovative. Everything 100 % Made in Germany and Switzerland!

Evaporation Technology

We offer the world’s largest selection of thin film evaporators and build customer-specific equipment for the evaporation of materials which are difficult to process such as viscous, fouling, and heat-sensitive liquids.

Drying Technology

Depending on the requirement, we combine and customise drying processes and components to suit the product properties so that, for example, toxic or explosive materials can be safely and efficiently processed.

High Viscosity Technology

Our thin film processors and large volume reactors for the manufacture and preparation of polymers are world leaders and guarantee the very highest quality and efficiency as well as excellent process results.

Get your free copy!

Discover how our intelligent solutions can streamline operations and boost productivity in our Smart Equipment flyer: